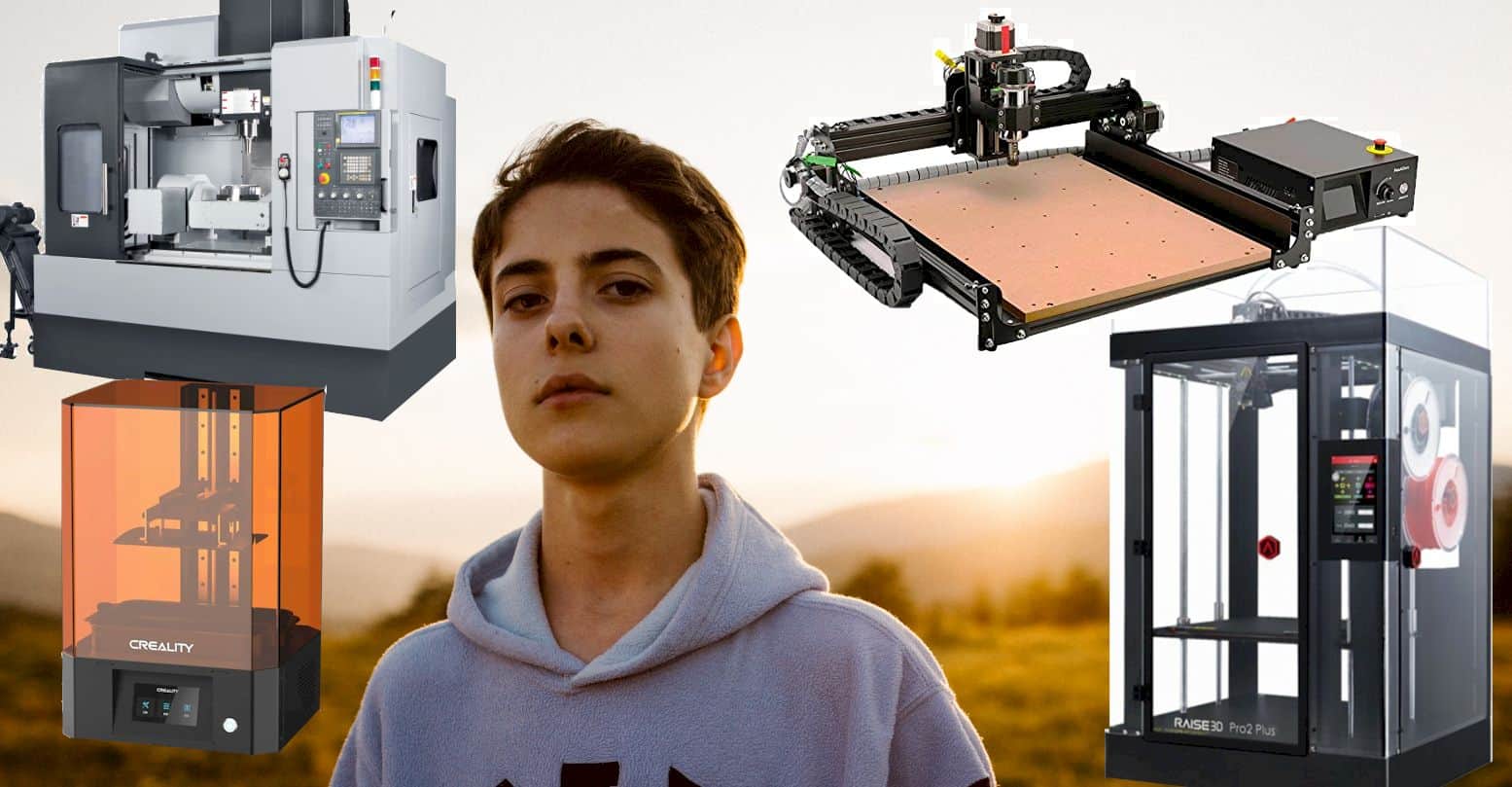

In creating custom-made models and parts, manufacturers rely on two competing technologies: CNC machining and 3D printing. Let’s take a closer look at these two manufacturing methods and compare CNC vs 3D printing. Let us discover what makes CNC machining better or what makes 3D printing tick with this comparison review.

Overview of CNC and 3D printing

CNC (computer numerical control) machining is a manufacturing process where pre-programmed code and software guide the creation of parts or products. This process is useful in creating basic to complex machinery parts, prototypes, and molds.

CNC has been around from the 1940s to the 1960s and was based on tools that were developed using motors. These motors moved the tool to follow points that were fed on a punched tape system. By the time analog and digital systems were available, modern CNC machines changed the way machining was done.

Meanwhile, 3D printing is a form of additive manufacturing that produces three-dimensional objects created from a CAD model or a digital 3D model. 3D printing refers to different processes, including depositing, joining, and solidifying a 3D object. There are many types of material used in 3D printing, and these include plastics, powder grains, and liquids. These materials are added layer by layer until the complete object is printed in 3D.

3D printing was conceptualized at the same time CNC machining was developed. The first patented 3D printing prototype was registered in 1971, and by the 1980s, manufacturing equipment and 3D printing materials were created.

CNC vs 3D Printing

A look at the type of materials, ease of use, accuracy, complexity, size limitations, costs, and environmental impact of CNC and 3D printing will help you understand how each technology differs.

Type of Materials

CNC machining and 3D printing are both compatible with a large number of materials. You may use metals, plastics, wood, and many other materials for both technologies. However, 3D printing is more commonly used for plastic materials; second only are metals and wood. In CNC machining, plastics are also commonly used, especially nylon, ABS, PC, PMMA, POM, polypropylene, and many others.

Possibly the most common material used in CNC is aluminum which is used in creating models and prototypes. Aluminum is the best because it’s recyclable and has awesome protective features. Aside from aluminum, companies use magnesium alloy, stainless steel, brass, and zinc alloy titanium.

3D printers make use of thermoplastics or plastics that melt, not burn when exposed to heat. Common thermoplastics include nylon, PLA, ABS, Ultem, and many more. Polymers are also used, which include wax, resins, and calcinable materials. There are specialized 3D printers that can print materials like ceramics, sand, and green materials or living materials.

Metals like stainless steel, aluminum, titanium, and many more are also used in high-end printing. Some materials can only be used in 3D printing like TPU and some superalloys.

Ease of Use

3D printing is easier and simpler to do compared to CNC machining. In 3D printing, you only need to prepare the file, upload the file to the printer and select the material filament. The printer is prepped up by heating the extruder and printing platform; as the printing commences, the technician does not need to stand by to wait. He can come back later when the 3D print is done.

In CNC machining, a technician needs to choose the correct tools, program the machine when it comes to the tools’ rotation speeds, cutting paths, and material repositioning. The technician has to constantly check the progress of the machine and afterward, work on post-processing of the finished product.

Machine accuracy, sizing, and complexity

CNC machining is far superior to all other types of 3D printing when it comes to sizing, accuracy, and complexity. Despite the ability of some 3D printers to create large volume prints, these cannot compare with CNC machining when it comes to the size of the parts.

3D printing is used to develop parts that have complex geometric parts. Supports are sometimes needed, but 3D printers can make parts that are impossible with other printing technologies.

Machine costs

Reasonably-priced 3D printers are now available for hobbyists, DIYers, and small companies. These printers are capable of printing different filament materials and making all kinds of models for different uses. Meanwhile, CNC machines, components, and accessories are very expensive.

Even the operational costs of these technologies vary. It’s easy to operate a 3D printer, and the materials or filaments are cheaper and easier to procure. CNC machinery needs a trained operator to operate, and the materials used to manufacture parts and components are also very costly.

Environmental impact

CNC machining cuts away raw materials, and thus, the excess is thrown away or discarded. These should be done responsibly and efficiently to avoid polluting the environment. In 3D printing, there is almost no waste as the material is built layer by layer. Some thermoplastics are recyclable too so in case you make mistakes, and you can always melt the material and feed it to the 3D printing machine. Also, some designs may require supports. This is the only material waste that 3D printing creates.

Benefits and drawbacks

CNC machining has the following benefits

- Can handle small to large volume prints.

- Very precise, can be used to create intricate models.

- Uses a variety of materials with aluminum the most common.

- Can be used to manufacture models and parts quickly.

- For projects that require quick turnaround times.

CNC machining drawbacks

- CNC machines require skilled operator guidance.

- These machines are heavy, bulky and therefore need a lot of space.

- These machines are very expensive and require training to use.

- The materials used to make CNC machined parts are also very expensive and harder to procure.

3D printing has the following advantages

- 3D printers are now available for all users.

- More reasonably-priced, high-value printers are now available.

- You can make complicated components for different industries.

- 3D printing is more affordable as materials/filaments are cheap, easy to procure.

- 3D printing creates zero waste except when there are supports needed.

- Some 3D thermoplastic filaments are recyclable.

- You don’t need expert training to use a 3D printer.

- 3D printers are smaller, handier, and can be used at home, work, or in school.

3D printing drawbacks

- 3D printing is slower.

- 3D printing may not be as precise as CNC machining.

- It is not for large-scale projects with quick turnaround times.

Which is better, CNC machining or 3D printing?

It’s hard to say which technology is better, but when it comes to large-scale industrial and commercial use, CNC machining tops 3D printing. When it comes to speed and project volume, CNC machining is still the best. For small to medium-scale projects that do not require quick results, 3D printing is the best choice.

When it comes to lesser environmental impact, 3D printing wins. And for overall cost, CNC machining is more expensive while 3D printers are now more affordable and more accessible.

When to use CNC machining and 3D printing

CNC machining is best for creating metal and metal alloy parts, molds, components, and objects. It is for the manufacture of custom-built parts as well as prototypes for many industries. CNC machining is used in large-scale manufacturing.

Meanwhile, 3D printing is preferred when printing parts and objects with complex geometric shapes. It is the technology used in printing plastic projects. Because 3D printing is very accessible, it can be used by hobbyists and small-scale businesses, and professionals.

Some industries merge CNC machining with 3D printing, especially when it comes to creating prototypes and intricate components. Some machines come with CNC machining features and are also capable of printing 3D objects.

FAQ

These are the most frequently asked questions about CNC machining and 3D printing

- Which is better 3D printing or CNC machining?

When it comes to surface finishes, CNC machines can produce objects with very smooth outer surfaces compared to 3D printed models. - Why is CNC machining very expensive?

CNC machining takes a lot of time to create a part as complex, and very large components need longer CNC machining times. CNC machines are also more expensive compared to other technologies. - Are there CNC machines for hobbyists?

There are CNC machines built for hobbyists like the BobsCNC Kit, CNC Piranha Fx, and the CNCShop CNC Engraver 3040T. - Is injection molding more expensive than 3D printing?

Injection molding costs less than 3D printing, especially when you’re able to make more products using your mold.

Conclusion

When it comes to CNC vs 3D printing, the winner depends on what you expect from a manufacturing/printing machine. If you plan to create machined parts on metal or alloys, then CNC machines are better. If you want to shape 3D objects with plastics, then 3D printing will give you great results. CNC machining is very expensive but is essential in many manufacturing companies and industries.

Most 3D printers are used in small to medium-scale businesses, hobbyists, professionals, and model developers. Find out the features, pros and cons, and differences of CNC and 3D printing to decide on the right technology that will work best for your needs.

Contents