While 3D printing is an enjoyable hobby, it also comes with problems. Sometimes, you will face issues that can ruin the whole experience of 3D printing for you. One of the most problematic issues is print layers not lining up because you can’t even get the proper design on the prints you want.

That’s why here I will dive deep into the issue and tell you why that is happening. I will also try to give some solutions that you can follow to get better alignment on the print layers.

So, if you are also wondering about the issue, stick with me till the end to find out the answers.

Why are some layers on your prints not aligning?

Well, there are several reasons for this problem to occur. There can be issues with your printer’s hardware, or you can have issues with the print settings. Whatever the case may be, it’s a problem that you have to pay attention to.

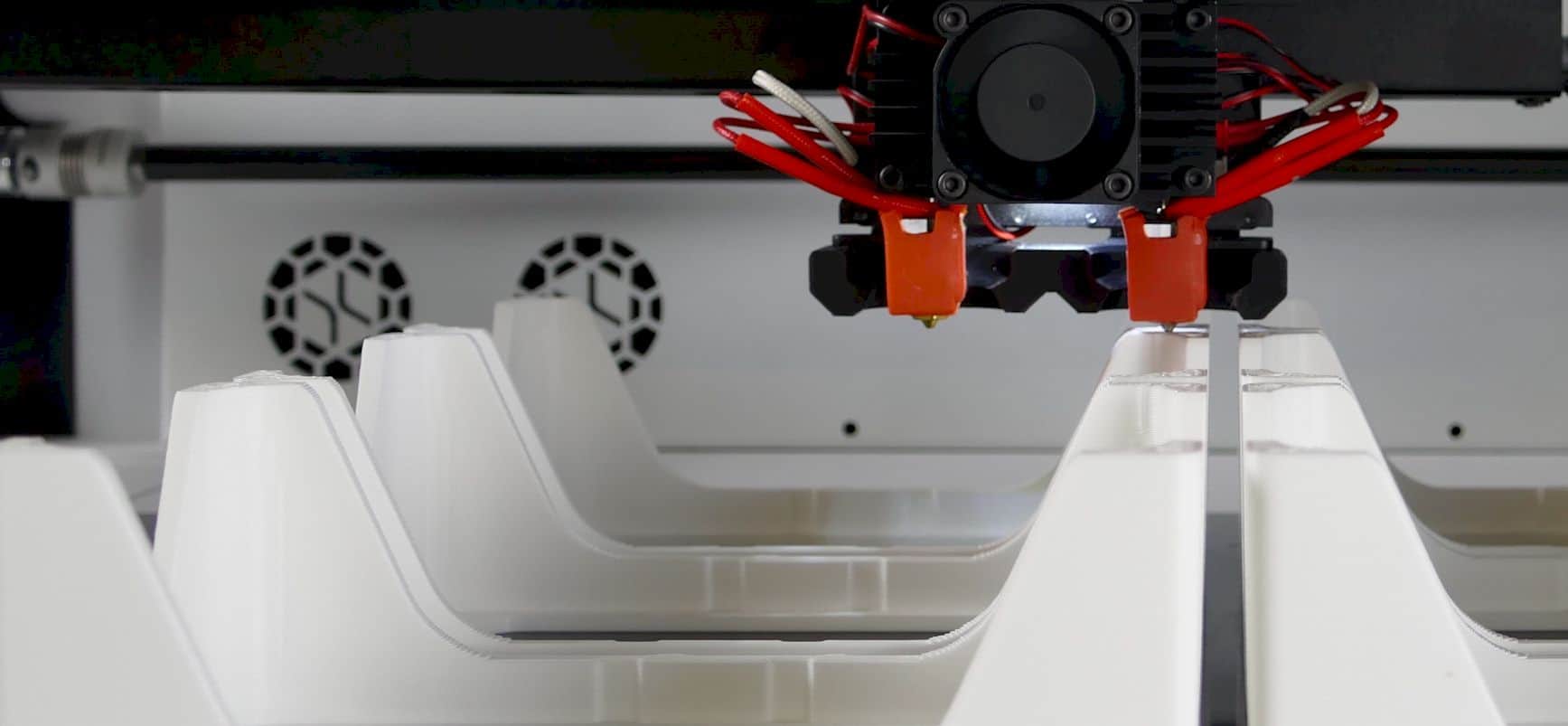

Among the hardware issues, one standard part that goes wrong is the belts and pulleys on your printer. If these belts and pulleys are cheap and don’t perform well, you will have misaligned layers. Since they are responsible for the movement of the nozzle, any problems with them will cause the layers to shift.

This can mostly happen when you have cheap quality belts or assembled the printer yourself. There is a lot of room for error when you assemble the printer by yourself. When you don’t have perfect alignment on the parts, you are likely to face misalignment issues on your printing as well.

Aside from that, another reason can be the material entanglement with the belts and pulleys. This happens when the filaments become loose while coming out of the nozzle. Later on, they get tangled with the pulleys while the nozzle keeps moving.

Another reason for this problem to occur is bent rods. If your 3D printer uses those threaded rods and they somehow get bent, there is a chance that it will cause print layering issues. Your layers will fail to align properly. These rods can easily wear or tear and get damaged.

Now, these are typically the issues you will face with the hardware. Other than these, there can be causes like overheating that misalign the print layers. Also, a print speed that is too high can cause this issue to happen.

Luckily, there are solutions to all these problems, and they aren’t that difficult either. So, let’s get through how you can solve the issue of printer layers not aligning.

Related: Creality ender 3 bed size vs print volume

How to get proper alignment on the print layers

Remember not everyone has to go through this process. Only do the following things if you are facing print layer alignment issues. Let’s get through all the processes you can try out one by one.

Adjusting the speed

The easiest fix you can start with is the speed adjustment. You have to see if the print speed you are using is a bit too high or not. When the print speed is high, there can be alignment issues. It also causes adhesion issues. Altogether you end up with poor quality prints on your models.

Now, the rate you should decrease the speed is 50%. Try getting the speed lower by 50% and see how that turns out for you. If it becomes too slow, you can make little adjustments from thereon.

Maintaining proper belt tension

If your printer uses belts and a pulley system, then you have to worry about the belt alignment. The belt can often go off track, and the tool head loses its position. That’s when you start facing print layer alignment issues on your 3D printer.

When the belt on your printer becomes loose, all you have to do is tighten the belt’s tension to fix the problem.

To check the belt tension, you can simply pinch them all together. If the tension is loose, refer back to the printer manual and tighten the tension following the instructions. However, if the belts are damaged or don’t retain tension after tightening, then you may need to replace the belt.

Related: 3D Printer Stops Mid-print

Lubricating the rods

Sometimes the rods on your printer can get jammed or slowed down because of dirt. Then, you have to clean them up and lubricate them to free up any jam on the rods. Make sure to check the bearing materials, as they will decide which lubricate you should be using.

But if you see lubricating the rods aren’t helping, you might have bent rod issues. To ascertain that, check for the rod alignment and see if it’s okay or not. In that case, it’s better if you can replace the rods.

Now, while replacing the rods, get some quality replacement. Try getting lead screws as they provide better durability in this scenario.

Choose a stable print bed

Another issue that can happen is an unstable print bed. There are some build plates out there that can move and wobble around. So, when you are printing, the layer alignments can go off a lot.

This is why, if you have a build plate that moves around a lot, you will need to replace it with something stable. You can also mean clips or screws to ensure the bed isn’t moving around too much.

Aside from all these, keeping the printer and printing also plays a role. For example, if your printer is on an unstable platform, then the nozzle will move around a lot while printing. This causes the layers to move as well.

Related: Setting up the Ender 3 Auto Bed Leveling

Wrap up

All in all, fixing the issue of print layers not lining up isn’t that difficult or costly. Once you figure out the issue and the cause, you can easily fix it without any trouble. Even though sometimes you may need to replace some parts, they aren’t that expensive at all. Also, you can replace them yourself, so that shouldn’t be a problem either.

Contents