Extrusion is the most common process used in 3D printing, and it’s often used to produce parts with complex shapes. But one issue that you may face when printing is “over extrusion”. It can damage the quality of your print. But do you know why it happens?

Over extrusion occurs when the printer’s build platform moves too far from your printing object, insufficient cooling, and incorrect filament diameter or more. As a result, you always get poor prints. By knowing about the signs and precautions, you can solve them.

That’s why today, I am here to tell you about the unknown causes, its sign, and how you will fix them. So let’s get right in!

What Is Over Extrusion?

Over extrusion occurs when a 3D printer starts pushing out a filament that exceeds the width of the nozzle and creates filament strings. Inside a 3D printer, layers can build one above the other by extruding plastic into many thin strips.

When an obstruction below the nozzle prevents it from moving freely, over extrusion can happen. This problem may create due to clogs, heatsink issues, physical obstruction, or incorrect slicer settings.

Over extrusion does not cause a problem using any specific 3D printer brand or types like FDM, Polyjet, SLS, or more. Because commercial 3D printers are more prevalent and they can observe systems. The most common commercial system that uses over extrusion is the Objet Connex series.

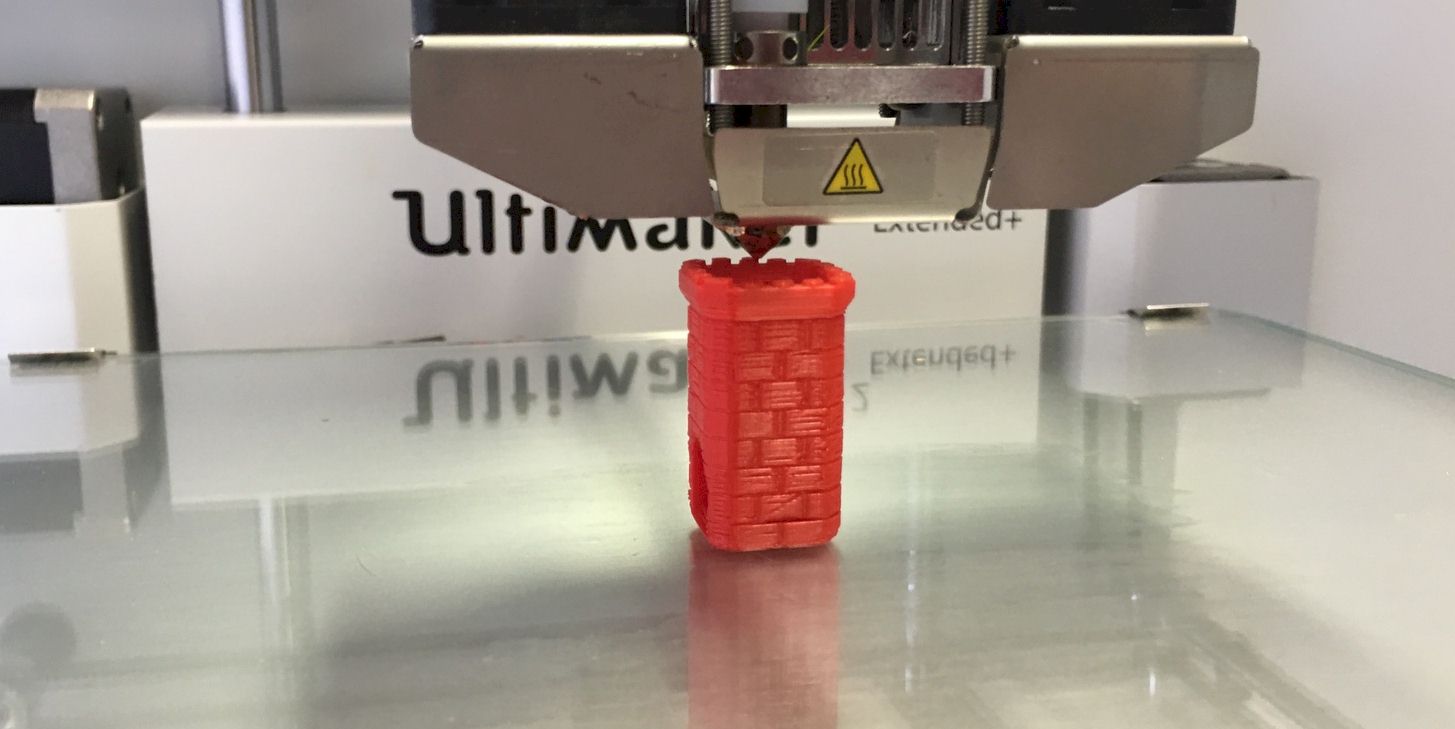

It can also occur on lower-cost desktop 3D printers that use Bowden-style extruders, such as the Ultimaker and FlashForge Creator printers. Over extrusion can cause issues with the final print, including poor part strength and durability.

What Causes Over Extrusion?

Over extrusion creates because of clogging the nozzle or by a communication error between the printer and computer. Let’s know about the cause of over extrusion:

When Using High Temperature

The filament extrusion temperature determines the flow rate of plastic via the printer. If the temperature is too high, it will become brittle and over extrude. A common reason for 3D printer over extrusion is making your printer compatible with different filaments like PLA or PETG over extrusion.

These materials need very different temperatures for them to print properly. If you use filament from one source and do not use an appropriate temperature setting, the printer may begin warping or start over extruding.

Filament will also sag when printing at higher speeds if you don’t have enough cooling during the print due to nozzle obstruction or insufficient cooling fans on commercial 3D printers.

Using High Extrusion Multiplier

Additional line segments will generate if the extrusion multiplier is too high, and the print will create over extruding. The amount of plastic that flows out of a hot end determines the ratio between the extrusion rate and the movement speed.

If you have a nozzle designed for extruding 1.0mm at 100mm/s, but you’ve configured your software to push out 2.0mm at 50mm/s, you’ll notice over extrusion.

Over extrusion issues when printing since more plastic is coming out of the nozzle. Most commercial 3D printers allow you to adjust this multiplier in their software, so it is important to find an optimal value for your printer before your prints begin failing.

Slicer Setting Errors

People use slicers’ software to convert 3D data into G-code. Different slicers have different settings that you need to adjust. These settings include layer height, infill density, and how fast a print moves horizontally.

If the layer height is set too high, it will create very thin layers. It will cause over extrusion since you will push out more plastic from the nozzle.

3D Printing Signs of Over Extrusion

Here are some of the common signs for you that you don’t know. Or if you already know, let’s know in detail:

When You Face Blobs or Stringing

If you look closely at an over extruded print, you can see that plastic strings droop down from the model. When a 3D printer is not operating properly and over-extrudes, the drooping will become more apparent.

In this case, you will have to cut off the extra material before printing again. It takes time to clean up these defects, and they can become much more noticeable when using certain colors of filament. Sometimes you may face 3d printing curling, and it can be one of the signs.

Poor Infill

Another sign that your 3D printer might be experiencing issues with 3D printing over extrusion is poor infill quality. In an extrusion-based 3D printer, the infill is an area of the model built in between each layer of filament.

If you force to extrude the print too much, it will retain air and not solidify properly, causing poor infill quality. When you are printing with a laser cutter or any CNC machine, be careful where your nozzle is inside the machine.

Sometimes 3d print corners are not sharp and it can be one of the causes of over extrusion. It can also cause ABS print curling, PLA curling, or other 3d printer filament curling.

Drooping Layers

If you notice that there are drooping layers in your print, it may signify a 3D print over extrusion. When extruded plastic, it first comes out molten and then cools and solidifies during printing.

Extruding plastic onto a layer that you already printed can make this layer much weaker and more brittle. The new layer becomes trapped between the print bed and the older layer, making it less effective when trying to print correctly.

It may create a 3D printer dragging filament. If you observe a droopy layer, it may be possible to see that there are strings of melted plastic from the nozzle being pulled onto the over extrusion first layer. It also causes PLA curling first layer.

How to Fix Over Extrusion 3d Printing?

If you notice that your extruder is over extruding and causing problems, you can fix it yourself by below. Here are some solutions to help you to fix over extrusion:

Low the Temperature of Your Printer

Lowing the printer’s temperature can be a good method for solving over extrusion. If you are using a hot end with a higher temperature, it is better to lower the temperature by around 5°C than before. Because most parts that use any plastic have a lower melting point than the hot end temp.

Modify The Extrusion Multiplier or Flow Rate

Single Nozzles require a higher flow rate to prevent jams. But when you use it in combination with a Bowden Element or Dual Extruder, the temperature will be higher than either extruder individually.

The higher flow will help slow down the filament traveling through the nozzle. It allows more material to melt before it reaches the extrusion Teeth. The higher flow also removes any potential chances of burning as nothing blocks the filament during its travel through the nozzle.

The Extrusion multiplier is another factor you need to adjust for better results. Higher Extrusion Multipliers mean slower extrusion rates. But using more material per minute passes through the nozzle and reduces its chance of jamming.

Check The Diameter of Your 3D Printing Filament

Every 3D Filament Manufacturing Company has a specific diameter range. The Recommended Diameter for most 3D Filaments is around 1.75mm to 2.85mm, although there are some exceptions. It is better to check the diameter of your filament before using it, as they may come in slightly different diameters.

Be Sure About Your Nozzle Diameter

To confirm the true size of the nozzle, measure through the nozzle. Some 3D Filament manufacturing companies have a specific maximum diameter of their hot end nozzles. Such as MakerBot, while others such as Ultimaker do not have a minimum or maximum diameter for the nozzle.

If you find your 3D nozzle has a diameter of over 3mm, you will need to either remove it from your printer or exchange it for another smaller diameter. You can also ask for assistance from your local 3D printing store in replacing it.

Go Through For Perfect Nozzle

Check your nozzle size and make sure that it is still in place. Nozzles can wear out after a while, and if they are too large, they will cause the printer to spit out filaments randomly.

If you find the nozzles broken, you will need to replace them from either a 3D Printing store or manufacturer.

Enough Cooling Fans

If you have issues with Ender 3 over extrusion, then there might be more than one problem with your cooling system. You can face over-extrusion because of having too many fans. When the hot extruder temperature exceeds 270°C, it will force the extruder to cool before pushing up through the filament.

As a result, causing problems such as drooping layers, sagging layers, and broken infill.

Check For Clogging Filament

In some situations, the filament may be jamming in your printer nozzle by clogging at the bottom of the hot end due to the over extrusion. To fix this, you can remove the filament from the printer and clean the nozzle with a wire to remove any clogs.

Increase Movement Speed

If the extruder speed is too low and cannot print material at an adequate rate, there might be a problem with how the hot end is cooling off. You can solve it by changing the speed of your printer.

Fix The Temperature Of Your 3D Printer

If your printer uses both extruders to print different kinds of filament, you may need to adjust the temperature settings for each filament. Because every filament has its temperature for printing.

Some printers have more than one temperature setting, giving you more control over different filament types and their outcome.

Enable Retraction

Sometimes, a clog can build up at the bottom of the nozzle and prevent it from producing the desired filament. In this instance, enable the retraction or reverse function of your extruder.

Retraction works by retracting or pulling the filament back into the extruder before it oozes out again. This method allows you to completely pull any leftover Filament and prevent any clogs from accumulating in a single place.

Change Your Extruders Speed

When using Repetier firmware, you can independently control each extruder at different speeds. It will allow each extruder to move independently of one another while printing. It can help avoid a build-up of filament on one side or the other.

Decrease the Relay Volume

Some 3D printers have a relay inside the stepper motor connected to a solenoid. The relay is there to help control the power provided to your printer’s stepper motors. And it can maintain its working order for long periods.

Change Filament Type or Brand

If your current brand and color are causing this problem, you might want to change it. Some brands may cause over extrusion. For example, PLA may cause extrusion than ABS due to different melting points and viscosities.

Tips on How You Can Avoid Over-Extrusion

- The best way to prevent over extrusion Ender 3 is to make sure your hot end has been adjusted correctly and clean your nozzle.

- The filament should push out smoothly with no inconsistencies or jamming when printing.

- When you have a damaged nozzle, you should replace it with a new one.

- If you experience Ender 3 Pro over extrusion, adding more cooling fans to the hot end can help prevent it.

- Your 3D printer may also have some troubleshooting tips for fixing this problem.

- Also, make sure your slicer will configure correctly to compensate for the heat of your print.

- To avoid over extrusion, use the perfect temperature or faster speed with enough cooling.

- You can either adjust your settings before starting any print or stop it immediately if it gets worse than normal.

- It is important to know that not all materials require the same heat or pressure to move smoothly through the nozzle.

- When you are printing, pay close attention to the temperature of your filament.

- Make sure never to set your feed length very high.

- Use a 3D Printing Pencil or 3D printing pen to adjust your model.

- Be careful about your printing nozzle.

Final Words!

3D printing can be a great way to produce unique objects quickly and cheaply. However, it is important to be aware of the risks associated with over extrusion so that you can avoid damaging your prints.

If you are experiencing issues with your 3D prints, please consult a professional for help. Finally, always use caution when using 3D printing. If you missed the precautions section, you can scroll up to know how to avoid excessive extrusion.

Happy printing!

Contents