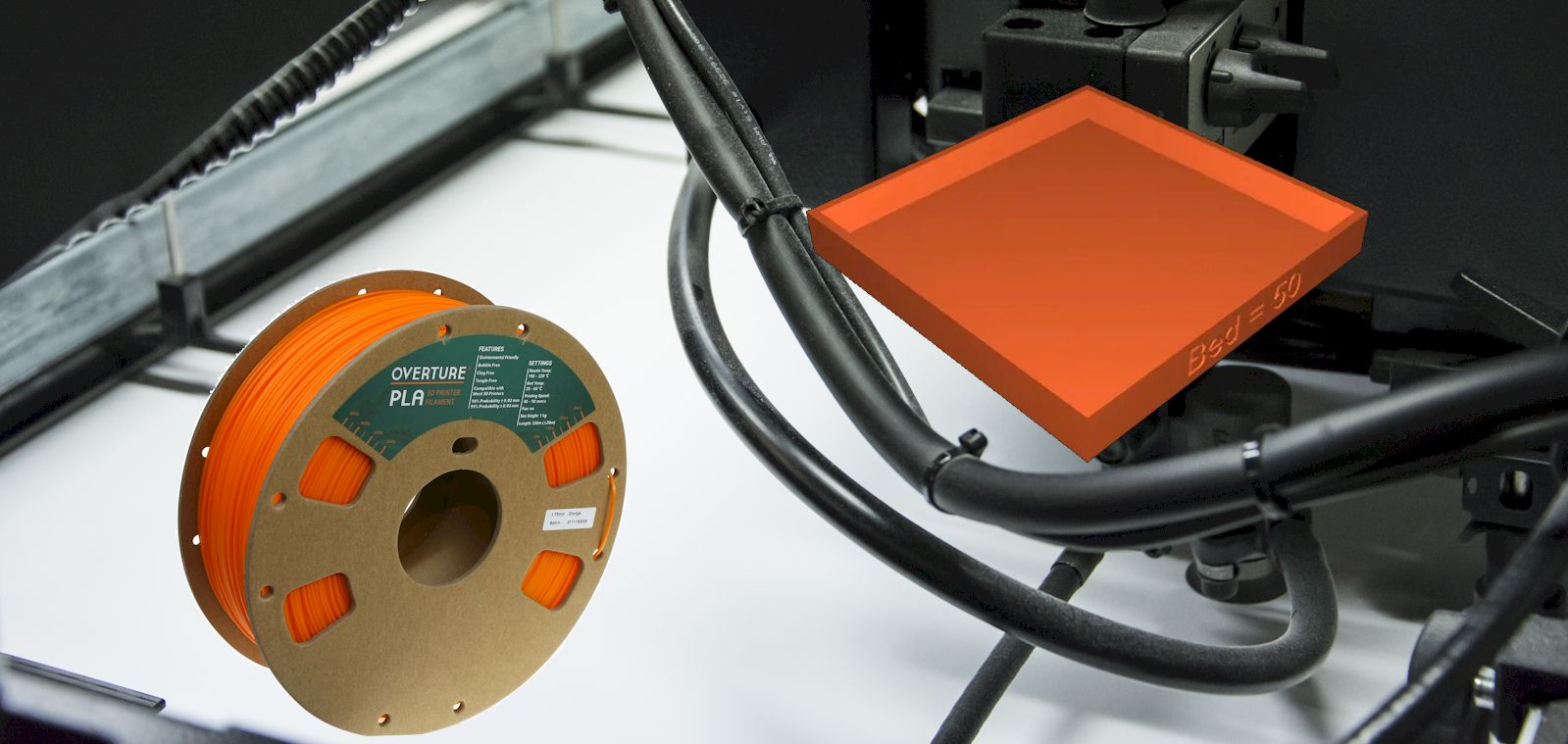

If you have a 3D printer at your home, you may know how to customize the heated build surface to create the perfect temperature for PLA filament. There is an ideal temperature for PLA material. If you use too high or too low PLA bed temperature, it can impact your printing quality. So, what is the PLA bed temperature range?

PLA tends to adhere well if you heat the bed between 60 and 70 degrees Celsius. On the other hand, the perfect temperature for heated ABS comes from 100 to 120 degrees Celsius. It would be best if you changed the temperature according to your material.

Here, you’ll get to know the temperature details for PLA filament. So hurry to learn more!

Problem: Not Sticking to the Bed

Select your printing software carefully so that your top layer applies to its ability. If you do not hook up the first layer effectively with your printing equipment, it may lead to major problems later.

The most common way of dealing with these first-level social networking site issues is to consider many common causes. Here I will outline several of these and give you the solution.

Probable Solutions

Here are some of the processes by using this, you can solve your bed sticking problem:

- When You don’t level Your Build Platform

If your printer has an adjustable bed, it has several knobs or screws, which you can use to change the bed’s position. If you do not level your printing bed, one of your underlays will be too close to your machine’s nozzle, which may result in an inaccurate print job.

The easiest way to ensure that you don’t need to adjust your bed when you adjust it is to make sure it’s flush and level.

- Nozzle Starts Working from too Far Away from the Bed

Subsequently, if you’re attempting to create accurately level prints, it still needs to determine that the nozzle is performing properly at the recommended height from the build plate. Your goal is to locate the extruder at the right distance from the build plate, not too far away and not too close. For strong bonding to the build plate, you must push your filament slightly against the plate.

In that case, click the Edit Process Settings menu item to open your process settings and set the Z-Axis global G-Code Offset on the G-Code tab. Flipping the Z-Axis x100 will let you make maximum flexibility in your nozzle placement.

Remember that the Z-axis G-Code offset is meant only to make small adjustments. Each layer of your part is only 0.2mm or less thick, so rather small adjustments can make a big difference.

- Too Fast Print Starts from the First Layer

Before extruding the next layer of plastic on top of the build platform, you want to ensure that the first layer can properly bond to the surface. If you print the primary layer of plastic too quickly, it might not have sufficient time to bind to the build platform’s surface fully.

That’s why it is typically helpful to use the first layer cartridge at a slower speed, so the plastic has enough time to bond with the bed. Simplify3D provides that feature in its editing process. Go to the Layer tab within the Backgrounds dialog box, and you will notice a setting labeled first layer speed.

- Cooling or Temperature Settings

The more you expose plastic to the passage of time, the more it shrinks. To present a practical illustration, envision a trip of 100 degrees centigrade prints out ABS plastic.

If the ABS part got to a bed temp for PLA is 30 C, its width would shrink by approximately 1.5mm. Unfortunately, the printer’s build platform will not shrink this much, as it is generally maintained at a constant temperature.

Hotbed printers intend to print high-temperature materials like ABS. So you can use a heated bed to protect against these negative repercussions. If you keep the bed at 110 C throughout the whole printing process, it keeps the first layer from cooling down for the rest of the print.

If a heated bed is available for use along with your printer, consider heating the bed to maximize adhesion. PLA is more frequently compatible with heated beds at a temperature of 60-70C, while ABS is compatible if the bed is at 100-120C.

You can adjust your Simplify3D preferences by clicking on Edit Process Settings and selecting the Temperature tab. Ensure to choose your desired heated build platform in the box on the left side of the page, then adjust the 3D printer temperature setpoint for your first layer. Click on the value you want to change and select your change beside the text box.

When your 3D printer bed temperature comes with a cooling fan, you can try disabling the cooling fan for these first few layers of your printer until you begin the print. Go to the Cooling tab and click Edit Process Settings to access this feature. You can change the fan speed setpoints in the upper left-hand corner.

If you are printing on ABS plastic, it is pretty normal to disable your cooling fan for the entire print, which increases the time a single setpoint produces. If you are working in a breezy environment, you may want to wrap the printer in insulation to keep the wind from affecting your part.

- The Build Surface

Plastics of a certain composition tend to bond better to different materials. For a printer, this means that the printer’s build platform material has a special composition for materials. For instance, some printers use a BuildTak sheet at the top of the bed that bonds well to PLA.

The manufacturer of glass beds, like Borosilicate glass, typically prefers heat-treated glass for ABS prints because this material works great. If you intend to place your model directly on the glass surface, you should consider cleaning the platform beforehand to avoid injury to the ABS during the printing.

Applying some ink or rubbing alcohol to your print blankets can look a lot better. If your printer does not have a special design material documentation kit to help eliminate adhesion, you have other options.

Different types of tape adhere well to 3D printing temperatures for materials; you can apply the strips of tape to the build platform surface, and can easily and quickly remove or change, especially if you want to print with a different substance.

Glow tape can fit PLA sticks better than ABS tape, commonly known as polyimide. Many users have also had great success using a finishing adhesive substance or glue spray on the top of their platform. Hair spray, glue sticks, and other sticky substances often work well if everything else has failed.

- Just Brims and Then Rafts

Depending on Simplify3D, you’re updating a small part that does not have enough surface to stick to the print bed. One option to increase this area would be to use its Simplify3D features. Among these options, one is the brim. The brim increases the width of the rim around your part like a brim does to a hat.

You can use this option by going to the Additions tab and enabling the Use Skirt Brim option. Simplify3D enables users to develop anatomically accurate rafts, which are also made to construct a comfortable base from which to recline.

Problem: Hot End Bad Sign

According to your demand, there is a fixed range of temperature for different types of materials. When you use PLA the ideal temperature range should be near 200-220 degrees Celsius.

When the layer of your printing is not attached to other parts, you may not follow the optimum temperature. When your extruder of the 3D printer is getting too hot, you may feel that the PLA filament comes more thin and soft. As a result, the printing model may end up cluttered.

Solution: Hot End Ideal Range

Choosing a single PLA print temperature would be ideal, but there isn’t one. Rather, there are several temperatures to choose from, depending on your needs. The best temp for PLA ranges roughly from 190 to 220 degrees Celsius.

If your layers are not adhering together, defecting your hot end can often solve this problem, but be careful. When the extruder gets too hot, the PLA filament becomes soft and prone to sagging.

Problem: Heated Bed Bad Sign

Since your prints aren’t sticking well to the bed, it is a clear sign that your bed is too chilly. Try to increase the temperature by just a hair, and the print putty should better adhere to the bed. You could also reduce the amount of heat you’re adding to the bed so that your prints do not develop with elephant feet.

Solution: Ideal Sign Heated Bed

I recommend you to use the ideal PLA printing temperature, particularly in the 3D printing industry, which is 70 degrees Celsius. This temperature doesn’t always coincide, though, as many poorly made 3D printers require a heated bed regardless of the temperature, and they prefer the printing temperature to be from 55 and 70 C.

How to Get Perfect Print on Different Surface

Here I have shared the experience of printing on different types of surfaces. So let’s know the details:

Printing Over the Blue Tape:

Painters tape, or Blue Tape, is one of the easiest and fastest ways to get a decent print from PLA. Blue tape is not the best, but it is easy to use and effective for the most part.

However, sometimes your supplies may pull the tape up off the glass during the printing procedure, and you may see some warping.

Here is a quick list of items you need to ensure you’re doing.

- Be sure that the Blue Tape creates an even layer. Don’t leave any gaps. Do not overlap the edges.

- Do not heat the bed when using Blue Tape, as it does not work well with PLA.

- Any tape strips that turn out to damage as you’re changing parts of your printing machine.

- You can replace the tape after a minimum of five copies have been printed on the press, or when parts no longer stick.

- If you have fine streaks on your first layer – ensure your print head is close enough to produce a good squashed layer of PLA.

- If the problem does not respond to this approach, try bumping the temperature setting to 5 to 10 degrees.

Printing On Glass with a Heated Bed:

- Be sure to have your glass bed level and PLA extruder temp at the right height when printing on glass.

- If you are not carefully regulating your extruder from above, your PLA will not stick to the glass, which will cause problems while printing.

If your first layer isn’t sticking, these are the steps you may follow:

- Ensure that your bed is level.

- Push the print head as close as you can so the first layer is nice and squished, and run the extruder long enough. So your print starts evenly.

- In Slic3r, you can allow varying degrees of lift, changing your layer stack from one to three, depending on the part.

- Based on the part, it goes up to 5, and I4 or 5.

- Clean the glass with denatured alcohol.

Printing on Polycarbonate

When you try liquid Polycarbonate, make it slightly slippery with vegetable oil. Polycarbonate worked, and the print came out well. However, removing the part proved challenging, and the benefit was not immediately apparent.

Final Words!

PLA is a good material for 3D printers because it prints quickly and evenly. However, the bed temperature needs to be kept low, so the material doesn’t shrink or warp. It is important to get familiar with the PLA bed temperature range so that you may print a good quality model.

If you still have any confusion about the temperature, please scroll up and have a look again. Happy printing!

Contents