Imagine you go for printing with PETG and end up with an unusual water sign in your filament. Damn, it’s so shocking because you had kept your filament safe! Now you may ask, “Why does PETG absorb moisture?”

Probably you kept it in a humid place for a long time, or you forgot to store your PETG in an airtight bag. That’s why it might absorb moisture. Keeping PETG in a low humidity place or storing it in an air-sealed bag will save it from absorbing too much water.

Before preserving, I’m helping you to know about the sign of identifying water in the filament. So let’s continue with learning how you can dry PETG filament as well.

Why Does PETG Absorb Moisture?

PETG filaments can absorb moisture because of an indication of bacterial and mold growth. These foreign objects can contaminate the printing process and affect the end-use quality of the products.

If you find your filament contaminated with bacteria and mold, then it can be a serious health concern and may cause harm if the end-user comes into contact. The most common way the moisture gets into the filament is through poor packaging or storing conditions.

When you put the filament into storage bags with wet clothing or in an unventilated area, then moisture will begin to infiltrate. Another major cause of moisture in filaments is improper storage for extended periods.

If a filament sits out for too long, it will eventually absorb all of the remaining moisture from the environment. While PETG has better thermal stability than PET, it could affect by extended exposure to heat.

How Do I Know If My PETG Filaments Are Wet?

When your filament has been infected with moisture, it is generally visible due to smell, taste, and color changes. There are different ways to tell if your filament is wet.

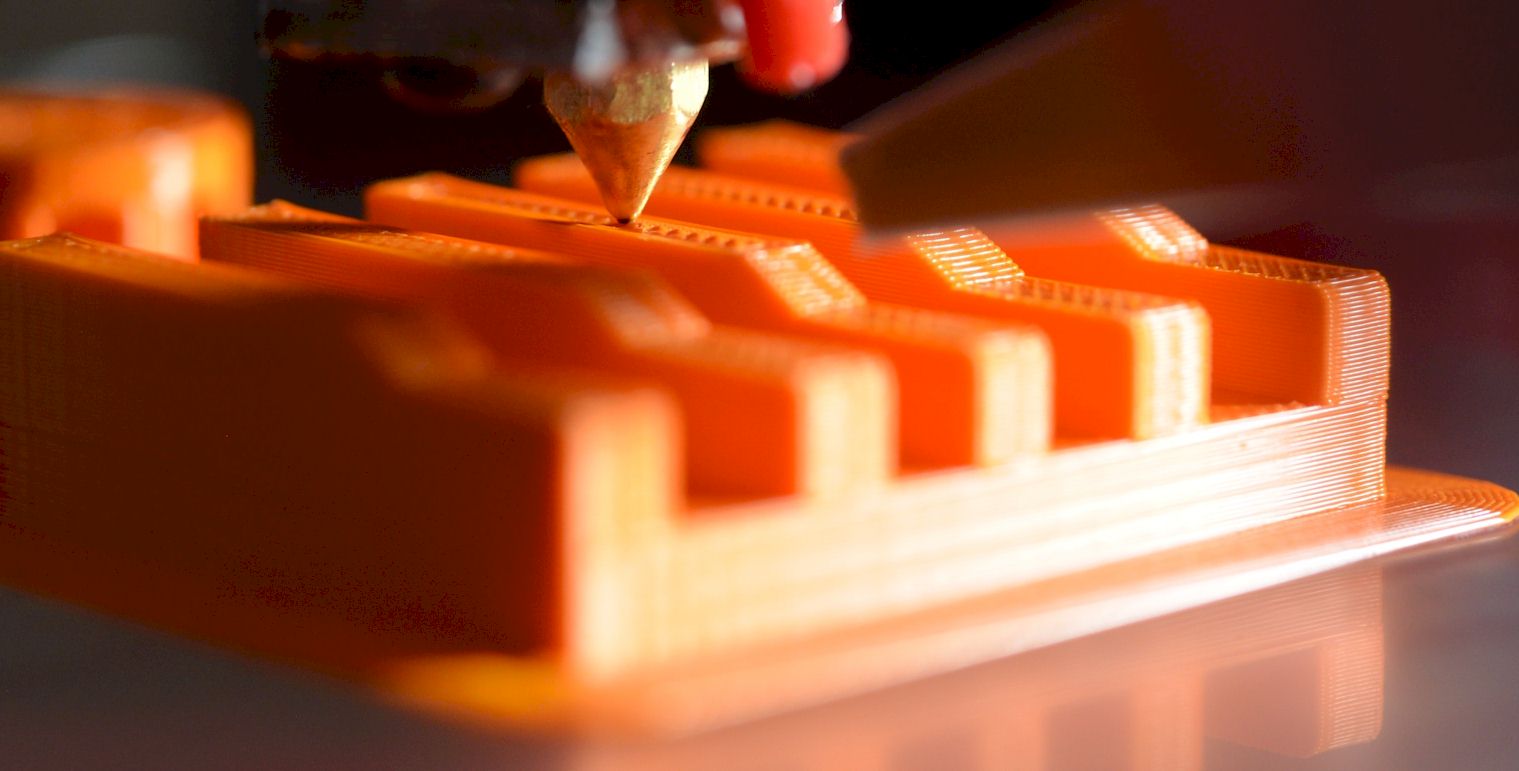

Different Extrusion

If PETG absorbs moisture, the molecular links tend to break. It can happen when you heat the filament too much at the tip of the nozzle. It can also happen after a long print with uneven force applied at different points and the extruder’s nozzle.

Adherence Problem

Another way that PETG can absorb moisture is through adhesion issues. PETG filament is softer than ABS. When it drops, the molecular chains open, and water vapor can enter the extruder’s nozzle chamber. It will result in evaporation from the heated nozzle tip.

Create Strange sound

If you have an unusual sound coming from your printer, listen to this strange sound. It’s commonly known as the “glub” sound, and it means that your filament has absorbed moisture. This sound comes from the water vapor from your filament evaporating from the heated nozzle.

Observe Steam in Nozzle

You can often observe water coming out of the nozzle under high force. When the extruder’s nozzle heats up, water vapor forms at its tip. If you’re using PETG, there’s a good chance that it is absorbing moisture due to this cause.

Adhesive Filaments

If PTEG won’t stick to your bed or other surfaces, it might be absorbing moisture from the air. The best way to check for this is by sticking a piece of paper on your print surface and seeing if it becomes wet after printing.

Decreased Layer Adherence

When printing with PETG, you may notice layers of your model peeling off the surface after several hours of printing. This is likely due to PETG absorbing moisture and becoming hydrophilic.

Imbalance Extrusion Lines

A final way that PETG can absorb moisture is how its molecular bonds break apart and open. It makes the filament hydrophilic, causing it to absorb water from the air. Once this happens, your extruder’s nozzle may become clogged up with a layer of water, and you will suddenly see inconsistency in your extrusion lines.

Observing Bubbling

If you notice PETG bubbling, stringing, or oozing on your print surface and do not force high to print, you can ensure that PETG absorbs moisture from the air. It can usually occur after printing all night long at low temperatures. If it happens to your print and you want to improve its adhesion, try lowering the temperature.

Water Spot on Filament

Occasionally there might be watermarks on your PETG spool. You can remove it by running an iron over them while off the spool and drying. This will remove any trapped moisture between the outside of your PETG spool and its inner plastic sheath.

Observing Steam in the filament

Absorbed moisture or material from the printer’s nozzle can also cause trapped steam to come off the filament.

No Filament Attachment

If your extruder’s nozzle has clogged with water, this can cause a layer of water to form on your PETG filaments. To clean off the water from your print bed, simply run the extruder’s nozzle dry for about 30 minutes and allow it to cool. Once cooled, use a hot air blower, or blow dryer to dry off the filament.

Why Should You Dry Your Filament?

If the filament is not fully dry, it causes a lot of problems for both the print and for your end result. In most cases, when PETG humidity is very high, the extrusion printer parts are unable to support the weight of the printed object. It has caused temperature variations and temperature spikes as well.

Extremely wet filaments may even start to mold or grow bacteria. Moisture also leads to poor adhesion between the print and the platform. Even if your print is dry and clean, this moisture can cause issues when the print starts to cool.

This moisture can lead to problems in the printing process itself. The wrong amount of PETG moisture or humidity in the air can cause bubbles and uneven printing results. So you need to dry your filament.

How to Dry PETG Filament?

You can use a few methods to dry your PETG filament. So let’s have a look:

- PETG drying temperature is 65 degrees celsius. By taking it and drying PETG in the oven up to 65 degrees Celsius over four hours.

- You can use a filament dryer set to make it dry at its highest setting for about 4 hours to 6 at 149 degrees F.

- Place your PETG filament in a plastic bag and place it in an airtight container or ziploc bag.

- You need to make sure that you have a sealed container that will block off any airflow and trap in heat.

- If you don’t have a desiccant-lined container, one option that works well is wrapping your spool in some aluminum foil and then placing it inside a ziploc bag.

- You can also use desiccant packages and place these inside the bag with your filament spool.

- Use a clothes dryer on low heat with no air circulation or drying agent mixed with your PETG filament.

- Finally, use your food dehydrator to absorb any moisture from the air.

If you really want to be sure that your PETG filament is dry, freeze the filament for about 24 hours by placing it in a ziploc bag or container.

How Do I Prevent My Filament From Absorbing Moisture?

- To help prevent moisture from infecting your filament, you need to store it in a dry area. Humid climates are not good for storing filament. If you live in a humid climate, it’s best to store your filament indoors and away from windows.

- Protecting your filament from humid air helps prevent it from being contaminated with moisture. Bacteria can break PETG if it comes into contact.

- The best way is to keep them in a sealed bag with dehydration after every use. Dehydration will help your filament or any type of material slow or prevent it from absorbing moisture.

Essential Tips about PETG Filament Printer

Does PETG need an enclosure? Here are some tips while using PETG filament for your 3D printer:

- Make sure you use PETG filaments under an enclosure if the environment is humid or has a high relative humidity level.

- If you are in a cold environment, always let the PETG filament underneath your printer warm up to room temperature before printing any objects.

- Never let your filament dry inside the printer, as it will lead to clogging and jamming issues in your extruder machine.

- Always dry them properly and make sure it’s dry for at least 1 hour before using them again.

- Don’t keep your PETG filament in the dark storage area. Because it will lead to moisture absorption, which will damage your filaments.

- If you have to store them in the dark, ensure they are kept under an enclosure to prevent humidity from entering.

- Don’t extrude many printing materials from your extrusion machine when using PETG. This will lead to clogging issues and jamming.

Final Words!

If your PETG filament dries out or becomes wet again, you are allowed to use it again by re-plugging it into the hot end. Check often to make sure that PETG absorbs moisture or not.

To prevent your filament from absorbing water, make sure you do not leave the nozzle tip exposed to a freshly printed layer of plastic for long periods.

Contents