Are you new to the realm of 3D printing? Then, you might have come across several things and have a long way to go. A heated bed is something to check out amongst them.

So, if you are thinking about exploring that area a bit more, then I have got you covered. Here, I will go through all you need to know about a 3D printer heated bed. Let’s not waste any more time and start going with it.

What is the 3d printer heated bed?

A heated bed is a kind of add-on or module that you can use for your 3D printer. This gives you more control over the cooling process of the 3D prints. This can eliminate a lot of printing issues related to the cooling method of your prints.

What are the benefits of having a heated bed?

Now, let’s start by seeing why you should even consider a heated bed. There are several benefits of a heated bed that you can’t overlook at all.

1. Better bed adhesion

When you have a heated bed on your 3d printer, you can expect a better adhesion of the material. The heat on the bed makes sure the filament isn’t cooling too fast. This gives the material to adhere to the bed properly.

You can expect a better quality on your 3D printed model with better adhesion. The results can be night and day with and without a heated bed.

2. It prevents any warping issues.

This is closely related to the adhesion factor I just discussed. When the adhesion on the printed material is not that good, the model’s corners detach. This results in filament curling, which is known as warping.

With a heated bed, you eliminate that possibility of material detachment from your prints. A heated bed makes sure there is a consistent temperature throughout. As a result, you get better adhesion. Adhesion can hold down the prints pretty well, so they don’t curl up or warp.

This is one of the most important reasons people get a heated bed. This essentially ensures better print quality and stops the waste of filament.

3. Assistance in removing a print

Having a heated bed helps detach the print from the surface very clean. You don’t have to go through much hassle while removing the print. It becomes infinitely easy and quick.

Related: How to Clean 3D Printer Bed

When the heated bed has cooled down, it helps the lowest layer with better contraction. As a result, the layer gets more rigidity and loosens up from the bed. All of these things make it far easier to detach the prints from your print bed.

4. It keeps the print environment warm.

When you have a heated bed on your 3D printer, it dissipates a good amount of heat around. This makes sure the paint doesn’t cool down too quickly. Especially if the printer is enclosed, you get this benefit even more. Because it mitigates the excessive cooling on the prints, thus giving them better quality on the prints.

Now, these are some major benefits you get from a heated bed. There are several other ones you get here and there, depending on the bed you choose. Also, the compatibility and features of your printer play a key role in further benefits.

The ideal temperature of heated bed for different materials

To get the best performance out of your heated bed, you have to know the temperatures for each material. Additional material yields different results in certain temperatures. If you use the same heated bed temperature for all materials, you may not achieve the desired results.

Without making it too technical and confusing, I will cut right to the chase and give you the numbers. You can follow these guidelines for getting the best performance from your heated bed with different materials. Let’s get started.

PLA

When you are using PLA, you won’t need too much heat in the bed because of the natural adhesive quality of the material. Having said that, you can surely get some better results with a specific temperature.

ABS

Unlike, PLA ABS materials are a bit tricky to figure out. Because of the sensitivity in ABS material towards the bed and ambient temperature, you have to consider some factors.

Having said that, most of the time, using a temperature around 105-to-115-degree Celsius works great for ABS material. However, this can vary depending on the ambient temperature.

A good idea, in this case, is to use an enclosure this makes sure the air temperature around your printer is always consistent and high. This way, the room temperature doesn’t have too much effect on the prints.

TPU

For TPU materials, you have to consider their elasticity characteristics while going for the bed temperatures. Usually, keeping the temperatures of your heated bed around 45 to 60 degrees Celsius will give you the most successful result with this material.

TPE

Just like the PLA material, it’s not that necessary to have a heated bed when you are using TPE material. The most common and preferable temperature to use for this material is something around 60 degrees Celsius. Still, if you are feeling to go more, you can be within the range of 60 to 120 degrees Celsius for good results.

PETG

If you are using PETG material, you don’t need to worry too much. The heated bed works great for this material if you keep the temperatures between 75 to 85 degrees Celsius. This will give you the best results while using PETG with a heated bed.

Nylon

When you are using nylon filament, you might want to have pretty high heat on the bed. This kind of filament likes to have good heat on them for the best results. Keeping a temperature between 80 degrees to 100 degrees Celsius works out the best.

Typically, knowing these values and following them should give you the best possible results. As you can already see, some sensitive materials like ABS need a bit of extra care. So, you must know the proper values. Staying within these ranges should be fine for you.

Types of the heat bed

Before diving into this, just know that it doesn’t matter what type of heat bed you have; the ideal temperatures stay the same. Let’s check out the different heat bed types you can get.

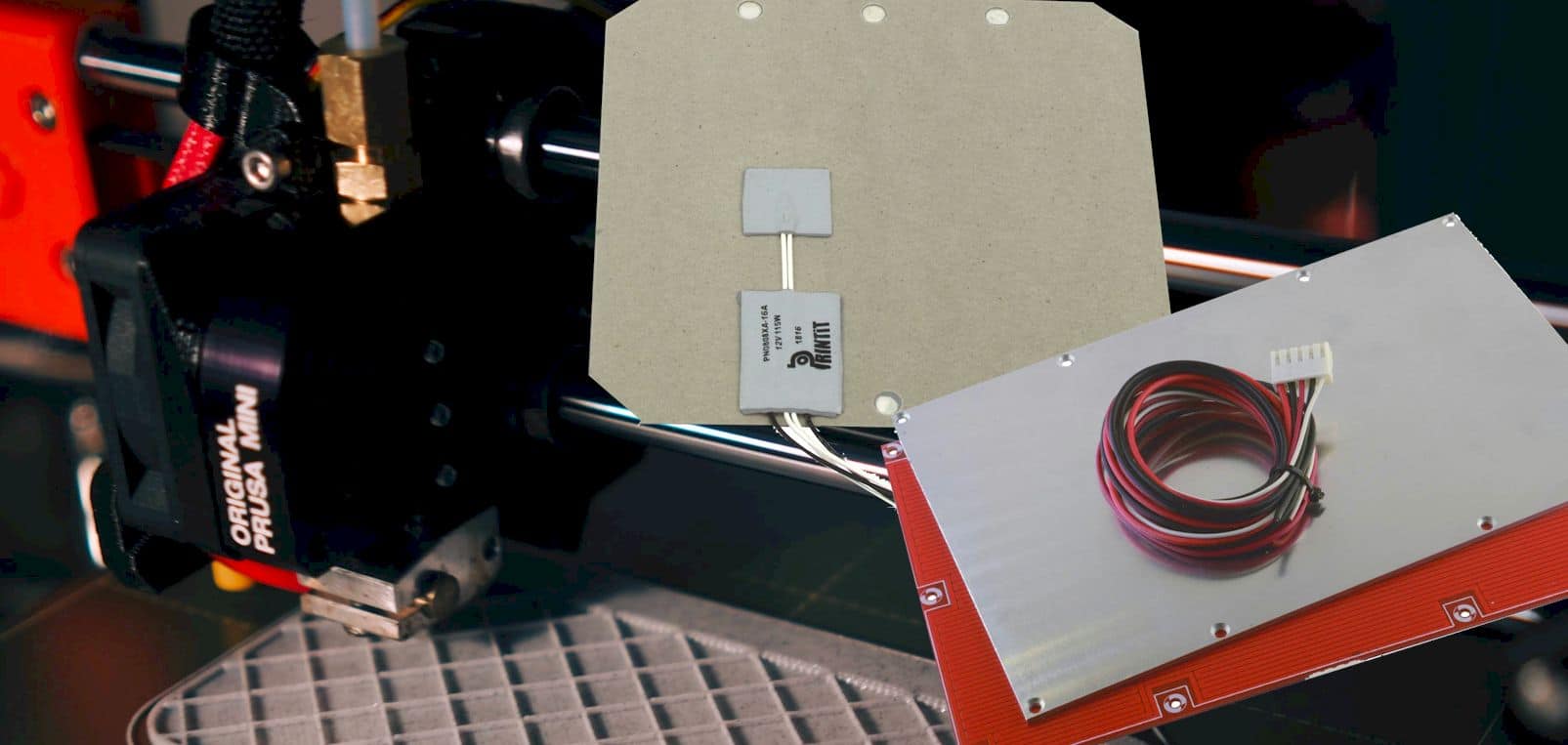

PCB heat bed

PCB heat beds are the complete form of heat beds you can find for your 3D printers. They are great in performance and affordability. There are several additional features that you can get based on the product you choose to buy.

A great thing about PCB heat beds is that they don’t need too much vertical clearance. You can easily adjust them accordingly, and they will provide you with an even distribution of heat.

However, there is a drawback with this kind of heat bed. It can be a bit slow in heating up. This especially happens when you are using another surface alongside this. For example, when you pair it up with a glass pane.

Polyamide/ Kapton Film Heater

Polyamide is a popular choice when it comes to surfaces for 3D prints. The heat resistance paired up with a higher adhesion, and smoother finish for PLA material makes them a common choice.

Now, on this one, you get two films of Kapton that have a heating element between them. This creates a Kapton film heater for you. The advantage of this is that it’s very thin, so installing it on is pretty easy. Also, it heats up very quickly, giving you faster results.

Aluminum Clad heaters

This is another source of heated bed you can get for your 3D printer. It’s super-efficient and also a pretty affordable medium for a heated bed. However, installing this one can be troublesome because of all the steps you need to follow for the installation.

Of course, I won’t be going through the installation process here. The installation process involves screwing this onto a surface to give you an idea. Then, there are several other steps you need to follow where you need a thermistor in case of certain conditions.

Usually, these are the typical types of heating beds you can get out there. You can choose one among them based on your preferences. What works best for you comes down to what you are looking to get, such as your budget, needs, and convenience.

Related: Creality ender 3 bed size vs print volume

Getting the best out of your heating bed

No matter which heating bed you get, there are some things you can do to maximize the performance you get from them. It’s not anything out of the ordinary; just making sure you follow them should give you the results you desire.

Here are the things you can try out to get the most from your heating bed.

Always lookout for the wrong temperature reads.

Yes, for the most part, the temperature of your heated bed stays stable. But there are times when the temperature may be displayed inaccurately. As time passes by, the temperature reading capability degrades. You can use a thermal monitor to keep up with the temperature readings.

You can always work on the printer firmware to fix those issues based on the deviations. You can also try different methods to correct the temperature you want to have for your material.

Don’t rush on reaching the temperature.

You can easily mistake not allowing the heating bed to reach the working temperature. Although, it’s not entirely your fault. Because sometimes, the temperature reading will tell you that it has reached the operating temperature.

So, when you rush with the print, you end up with prints that don’t adhere properly. This results in poor-quality prints. Even though there is no fixed time, most printers will take around 10 minutes to reach the working temperature on the bed.

Irregular distribution of temperature

While sometimes you may see that, the heated bed has reached its working temperature; it may differ from that. There can be inconsistency throughout the heated bed temperatures.

This means the heated bed may have reached the working temperature in specific parts and hasn’t been done in some parts. The uneven temperature on the bed results in producing very bad quality prints.

Some parts of the print will adhere to the bed, while others may not work out that well. As a result, you end up having warping issues on your prints. The solution to that is pretty simple. You just leave the heating bed to heat up thoroughly to get an even temperature on the complete bed.

Make sure to use precise PID tuning.

The correct PID tuning on your prints results in various imperfect surface issues. It can also cause ribbing problems in the prints. This happens with higher-temperature materials in particular.

Simply turning the PID properly can get you rid of this issue altogether. You won’t have to worry about these issues with the proper PID tuning. Even using the stock settings, going through accurate PID tuning is still worthwhile.

Aside from all these, you can always be careful of heat safety. Whenever you are using a temperature above 60 degrees Celsius, it can damage your skin.

Related: Setting up the Ender 3 Auto Bed Leveling

Wrap up

In conclusion, this whole thing is just the beginner’s guide towards a 3D printer heated bed. Knowing these things allows you to know about the entire thing and dive deep into the individual parts. This is an excellent place to start if you wonder about heated beds.

As you can tell by now, you can quickly get many benefits from using a heated bed for your 3D prints. And if you want the best possible print quality, then getting a heated bed for your printer is the first step towards that.

Contents