PETG, also known as polyethylene terephthalate glycol-modified, might come off as a hefty term. However, it’s the most common and regularly used kind of plastic around the globe.

This type of plastic is always on the rise and is demanded everywhere. You can find them in genuine plastic materials, utensils, toys, containers, bottles, and so much more.

But most importantly, it’s a recyclable plastic that can be injected or blown into materials so that they can take shape, make bents, cuts, and more. In the world of 3D printing, it’s pretty exciting and necessary to know how it’s done.

Let’s dive in to see a tad bit more on PETG stringing, 3D printing filaments on PETG, how to fix and avoid errors during these prints, and more!

PETG Stringing Issue:

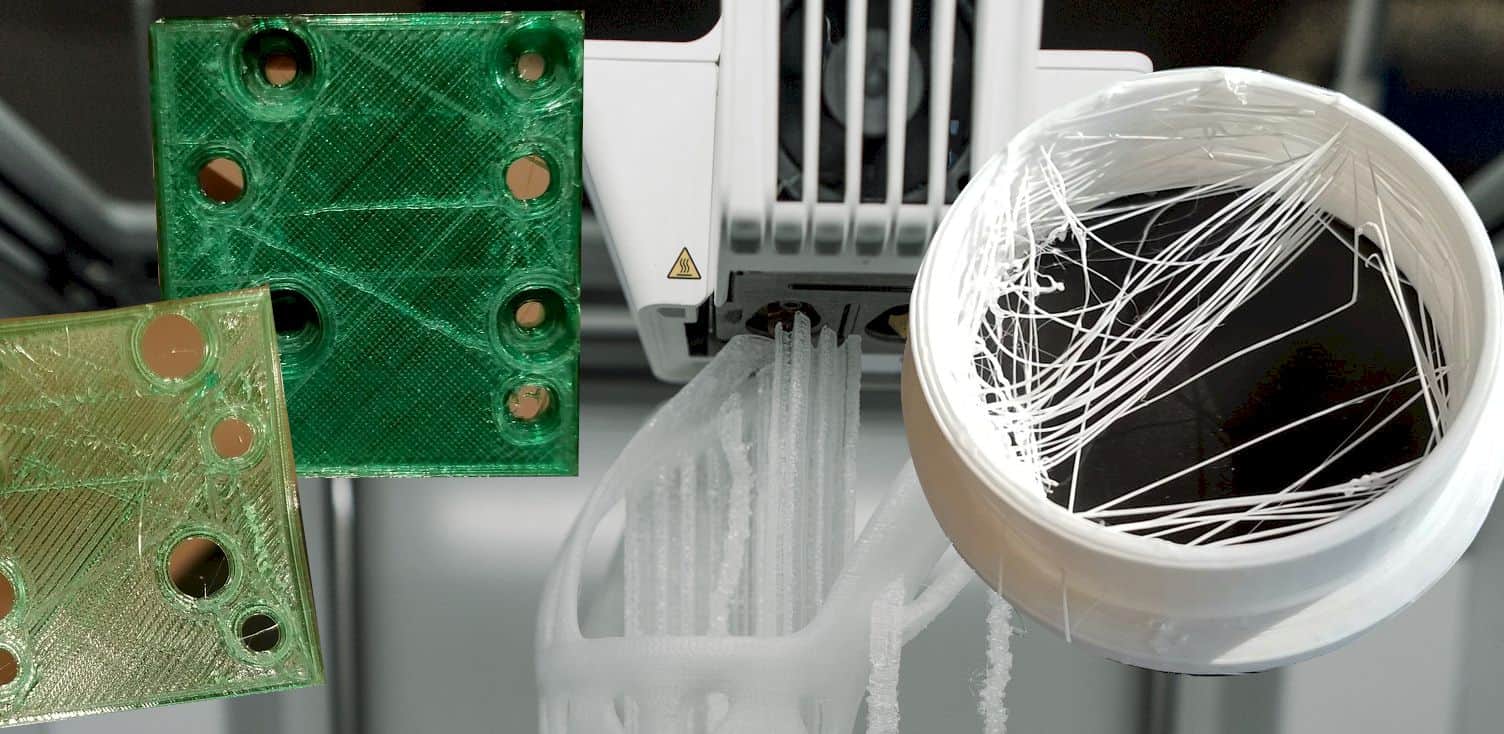

During 3D printing for PETG, you must place special care into it so that the result isn’t destroyed by stringing.

The good news is that this issue isn’t entirely too rare, and what’s even better is that it can be controlled and rectified. Stringing usually occurs because of the high melting temperature and high viscosity levels.

This excessiveness results in drips from the nozzle when the operator moves. Therefore, it is deposited in the model as strings.

Related: Fix PLA Stringing

How To Avoid The Errors During Printing:

Honestly, dealing with the results of 3D printing with PETG can be overwhelming for too many reasons. But when worst comes to worst, the results become entirely useless. This is why you must counteract a scenario before you begin printing.

Now, this is where sample models of 3D printing can save your day and eliminate any errors that you might face. Sample models are smaller products where you can visibly see the mistakes; thus, rectifying and comprehending the errors are easier.

Moreover, sample prints come in handy while working with demanding filaments and mostly if you’re inexperienced with 3D printing overall. With proof prints, you can’t waste much material. Therefore you end up saving lots of expenses too.

This comes even handier if you’re working with larger orders. For these cases, it’s vital that the settings must correspond a hundred percent to the model and filament’s requirements.

Related: PETG vs PLA

How To Decrease Stringing On PETG:

Since we’re all here to learn how to perfect 3D printing for PETG, let’s see how we can keep it controlled and minimize stringing.

Reduce the nozzle’s temperature

The temperature of the nozzle being used during 3D printing significantly influences the filament’s viscosity. Materials like PETG can be heavily manipulated because it becomes too fluid when the melting temperature is reached.

On the other hand, if the temperature is too high on the nozzle, you will have unwavering strings. If that’s the case, a test print in constructing a temperature tower can be beneficial. This will help you find the nozzle’s perfect setting with just one shot.

Consequently, you should also practice being cautious during this stage. If you lower the temperature too much, it could expand the structure’s surface. Therefore, having a balanced temperature is an absolute necessity.

Increasing the traveling speed

This method is also great at preventing PETG stringing. If the nozzle moves fast enough between the two points, there’s lesser time for the filament to drip out. This has a higher advantage comes from working at higher temperatures, as the PETG liquefies even faster.

It’s ideal for boosting up the speed gradually; for instance, ten millimeters per second works excellent. This will also enhance your opportunity to adjust the values precisely of the printer’s characteristics and the model. You can also determine your desired speed by giving trials with test prints. If the value you’re working with is ideal, there will be no visible stringing.

Minimize the traveling distance and enhance the retraction

Raising the retraction could minimize the threads in a model. Most of the time, this turns out to be quite effective.

The phenomenon works because the extruder motor pulls the filaments out of the nozzle during the course of the retraction. In this manner, counteracting the dripping process can be done by raising the retraction by one millimeter.

And the speed shall be boosted by five millimeters per second. However, these can only serve as basis levels. Thus, you can adjust the setting until you get your desired results for the model and printer. It’s also highly beneficial to reduce the traveling distance.

This setting lets the printer decide how far along should the printer’s head travel before the filament retracts completely. With lower values, you can ensure zero stringing even with shorter distances.

Related: Best Filament for Ender 3

Tips On Fixing/Avoiding Strings:

Here are a few tips that can help you maintain and implement a great 3D model for PETG. These tips will help you in the long run, especially if you’re a newbie who doesn’t want to waste any models and trials.

1. Resistance

There must be resistance against chemicals such as solvents, alkali, and acids for the material’s characteristics.

2. Density

The materials must have a density of around 1.27g/cm cube, which is higher than ABS and PLA.

3. Temperature

PETG requires a typical temperature of 220 to 265 degrees Celsius. However, before heating the nozzle, you must comprehend that the hotter ends have PTFE tubes incorporated at 250 degrees Celsius.

Therefore, anything that’s hotter than this might damage the ends. When the nozzle temperature is too high, it will lead to oozing and stringing, whereas when it’s too low, it will cause the extruder to skip. So, you can start at a low temperature of 220 degrees Celsius and make a few test prints.

4. Glass transitions

Glass transitions temperature must be 80-degree Celsius.

5. Supports

PETG can have a pretty good adhesion layer; thus, it might be challenging to eradicate the supports.

On the one hand, if you have dual extruders, you can go with soluble filaments, and on the other hand, for single extruder printers, leaving a gap between the part and support should do the work.

Leaving a 0.1 mm gap is worth more than plenty to begin and attain outstanding results. However, with the other parameters, you have the advantage of playing around with the values that fit you best.

6. Pressure

You must print gradually at all times and increase the pressure at the back of the nozzle. It’s more likely to ooze out when traveling between the printing areas.

7. Z-hop

It’s better if you can turn off the Z-hop completely. The pause and lift action of the nozzle can pull the PETG materials out of the nozzle and thus, result in stringing. When the Z-hop is disabled, and there’s sideways jerk while traveling between the printing areas, it’s likely to shear off the stringing effect even before they get the chance of forming.

8. Model

Choosing the correct PETG model can also deliver immensely in creating a neat and clean model. Therefore, before purchasing a 3D printer, you need to take a gander at its features. This is specifically necessary if you want to limit yourself to one filament.

Thus, it’s needed that the 3D device accommodates that only require that you have and delivers high satisfaction. Needless to say, bagging the first 3D printer that you come across is a big no-no. Flip through a few reviews and models to get a clearer idea of how and what they’re made of. The quality and features can vary significantly.

Thus, the prices will change as well. On the other hand, solely basing your decision on your budget will be wrong too. If the features can’t tailor to your needs, it’s not worth the hassle.

9. Retraction

Increasing the retraction speed will decrease the stringing. However, some filaments tend to break away from the molten points if the retraction comes too fast, which can cause them to ooze outside. To find the correct setting, it’s necessary to give a few trial and error runs. PETG likes to be retracted twice as PLA or ABS.

Related: Best 3d printer for flexible filament

FAQ:

- Is PETG suitable for 3D printing?

PET has become incredibly renowned for its adaptability. The FDM 3D printing material in the modified version is known as PETG. It’s affordable and reliable and offers users multiple designs and tailors to engineers too.

- Is PETG stronger than PLA?

PETG is more flexible than ABS and more robust than PLA.

- Why is it difficult to work with PETG?

When the extruder temperature is too low during prints, PETG filaments don’t flow and become challenging to extrude. Therefore, printing with the right temperature in the nozzle is an absolute must.

Wrap Up:

We’ve come to the end of knowing how to stop PETG stringing. In reality, it might get challenging and quite intimidating to implement the act rather than skimming through it. This is why for optimizing end results, test runs are a must.

The art of modern technology, such as 3D printing for PETG, can accommodate and guide you in countless ways once you get it right. Customizing real-time art has never been more fun and crucial ever before.

The only challenge that you’re left with now is that you have to implement what you learned in our article. To avoid stringing on PETG, you need to be precise and careful during each step. If you can manage to do so, the 3D printing of PETG will come out seamless and visually pleasing.

Contents