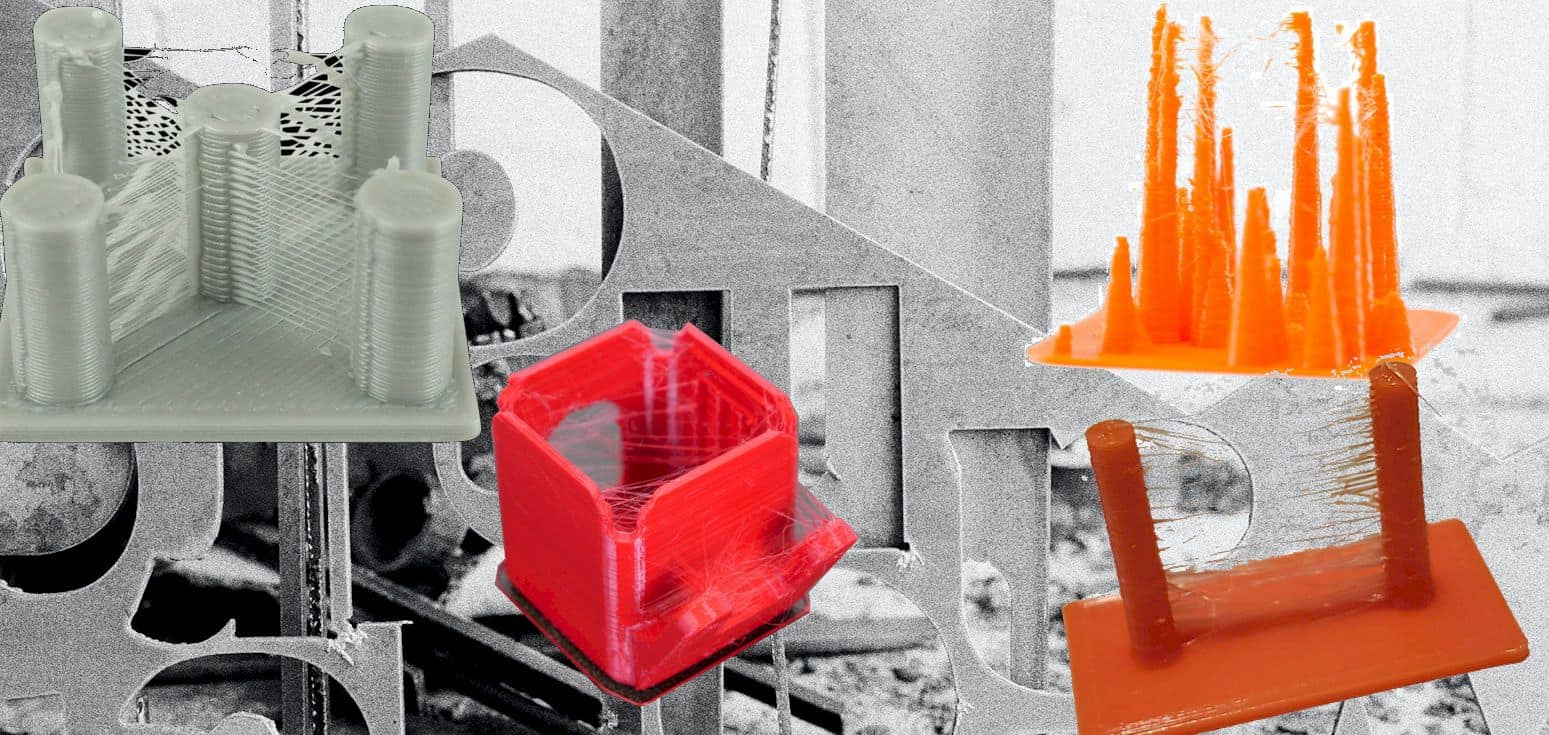

PLA stringing in your 3d printer can give you nothing but frustration as you get strings of melted plastic instead of the object you desire for. Many people these days don’t actually know how to reduce stringing pla and what things should be kept in mind to get rid of it.

Believe it or not, pla stringing is a common problem that the majority of 3d printer users face at least once in their entire life. But luckily, I’ve got some essential tips for you, which will be effective in terms of fixing those bummers.

So, from avoiding printing with higher temperature to cleaning the nozzle of 3d printer thoroughly, make sure you follow every single tip that I’ve mentioned right here down below.

How to Prevent and Fix Pla Stringing:

- Avoid Printing with Higher Temperature

- Activating Retraction Settings

- Preventing Filament from Moisture

- Cleaning the Nozzle Thoroughly

What Causes Pla Stringing in 3d Printing?

It’s definitely a good idea to get familiar with the common causes prior to getting the solutions straight away. So check out these couple of reasons which are straightly connected to the 3D printer stringing issues. Such as:

- Don’t maintain the retraction distance and speed in the way it requires

- Using extremely higher temperatures while printing

- Utilizing a nozzle without cleaning it, especially which is too jammed or clogged

- Some filament objects tend to absorb excessive moisture than usual. Using them is one of the common causes behind stringy 3D prints

Related:

How to Prevent Stringing 3D Print – Essential Tips to Follow:

Alongside the several causes of 3D printer stringing, a few solutions are available for you as well, for which you can reduce stringing in the best way possible. The majority of cases can be solved instantly by bringing some changes in your 3D printer setting, for instance: changing the distance, speed, temperature, or extruder speed.

But this won’t work at all if your printer has already become stringy! In that case, following the below-mentioned salutations have no better choice! So without further chit-chat, let me teach you how to stop stringing 3d printing:

1. Avoid Printing with Higher Temperature

As you already know, one of the common causes behind 3D printer stringing is to use an excessive amount of temperature while printing. So the solution is obviously to decrease the temperature as much as possible and look for the results.

By doing so, you’re allowing your device in terms of extruding pretty minimal material, creating the chance of less stringing. And note that materials of extremely higher temperatures tend to string on account of the massive heat on liquidity or viscosity of the filament objects.

Is PLA the ideal choice? Well, there is no doubt that it’s a comparatively low-temperature filament. Nevertheless, it can also be ended up with stringing issues. So let’s see how to get rid of Pla stringing 3d printing:

- While printing, use the reduced amount of temperature possible and look for improvements. Also need to confirm that the temperature you’re using is suitable for the existing filament.

- PLA is the ideal filament in such cases as it melts at a minimal temperature pretty efficiently. When you reduce the temperature, it’s equally necessary to turn the extrusion speed down.

- Feel free to do an experiment a couple of times, getting familiar with the right temperature as different objects require a different range of temperatures. To ensure excellent adhesion, I’d suggest printing your very first layer at a temperature of 10 degrees.

2. Activating Retraction Settings

The study proves that 3d printing stringing fix can be done once you activate the settings of retraction in the way it needs. By doing so, you’re reducing the overall pressure from your melted filament, decreasing the chance of dripping it while turning from one to another direction.

- The settings of retraction can be actuated by default. However, it would be best if you looked for the settings again in case you notice oozing or stringing.

- Allow the setting in order that the object of your selected filament gets the ability to pull always back once the nozzle makes an entry to a space that’s completely open, especially where 3d printing isn’t needed.

- Implementing the effective “combing mode” is a wise decision; why? Because it won’t travel anywhere except for where you already have done printing. I’d suggest taking help from the “Retraction Test on Thingiverse” by downloading it. In this way, you’re allowed to test your overall retraction settings like a pro.

Note: The retraction distance of 7mm and a speed of 70mm/s works pretty well; however, you can also get your desired result getting a bit lower.

3. Preventing Filament from Moisture

Indeed, a filament object is known for absorbing moisture and turning into bubbles, especially after getting heated. Unfortunately, these bubbles tend to burst, resulting in forcing the PLA filament to drip. And this way, the nozzle starts causing issues with oozing and stringing. Needless to say, a couple of filaments are poor in quality compared to others like HIPS and nylon.

Once the moisture gets mixed with any materials made of plastic, it may become steam and the possibility of stringing increases gradually.

- Always try to store your filaments in a specific box or container that is perfectly protected and airtight. Those containers should definitely have capabilities of preventing moisture.

- According to experts, you better dry out your PLA filament in case that’s included with moisture. What to use in terms of drying it? Well, I’d say an oven can be the right choice, which has to be used by setting up the temperature at a pretty minimal range.

- Get your hands on the filament that’s known for absorbing very less moisture compared to Nylon and stuff like that.

4. Cleaning the Nozzle is a Must!

While printing, many of your find some plastic particles inside of it. And if you keep them without any cleaning, they get stuck and it becomes tough to get rid of them.

It occurs more often when a user goes for printing with materials of higher temperature. As a result, I always suggest getting your hands on the materials known for lower temperatures, including PLA and ABS.

Needless to say, the nozzle is a pretty sensitive and of course, a vital part of your 3d printer. So, to reduce stringing, ensure to follow the tips given below:

- Before you start printing, make sure your nozzle is spick-and-span or free from any dirt particles. If not, go for cleaning it right away using a brush of metal wires. No need to be worried even if you don’t have a specific brush for cleaning; a regular brush can also come in handy

- According to professionals, it’s a smart move to clean your nozzle after each use. Thus, it turns way easier in order to get rid of the liquid-heated residues. Using acetone is a good idea in terms of cleaning the nozzle, especially if you’re printing for an extended period of time

Tip: If you tend to switch from one filament object to another, cleaning the nozzle is considered a must to reduce 3d printing reduce stringing.

Related: How to Glue PLA

When it Becomes Necessary to Replace Nozzle?

Are you still noticing pla stringing even after cleaning it up thoroughly? Most probably, the nozzle becomes completely damaged, poorly drilled, or might be corroded so badly! In that case, there’s nothing to do except for replacing the nozzle with a new one.

So I always recommend keeping the nozzle of your 3d printer as much cleaner as possible, and that too after each use. By doing so, it won’t get jammed or corroded too early, resulting in an extended lifetime of the nozzle.

Related: How to store PLA filament

Wrapping It Up!

Preventing and fixing pla stringing isn’t a challenging task anymore as I’ve shown you all the essential tips right here through this article. By using reduced temperature while printing and cleaning the nozzle after each use, you’ll be able to keep your 3d printer out of those problems.

But in case you face those annoying situations, feel free to utilize the tips and techniques that I’ve mentioned above.