If you have been in the printing industry, you might have terms Mk8, Mk6, Mk10, among others. These terms are confusing, especially for newbies. Luckily I am here to try and reduce that confusion.

To start, we will explain what mk8 and Mk10 are. We will then tell you why they are regarded as the best in the market.

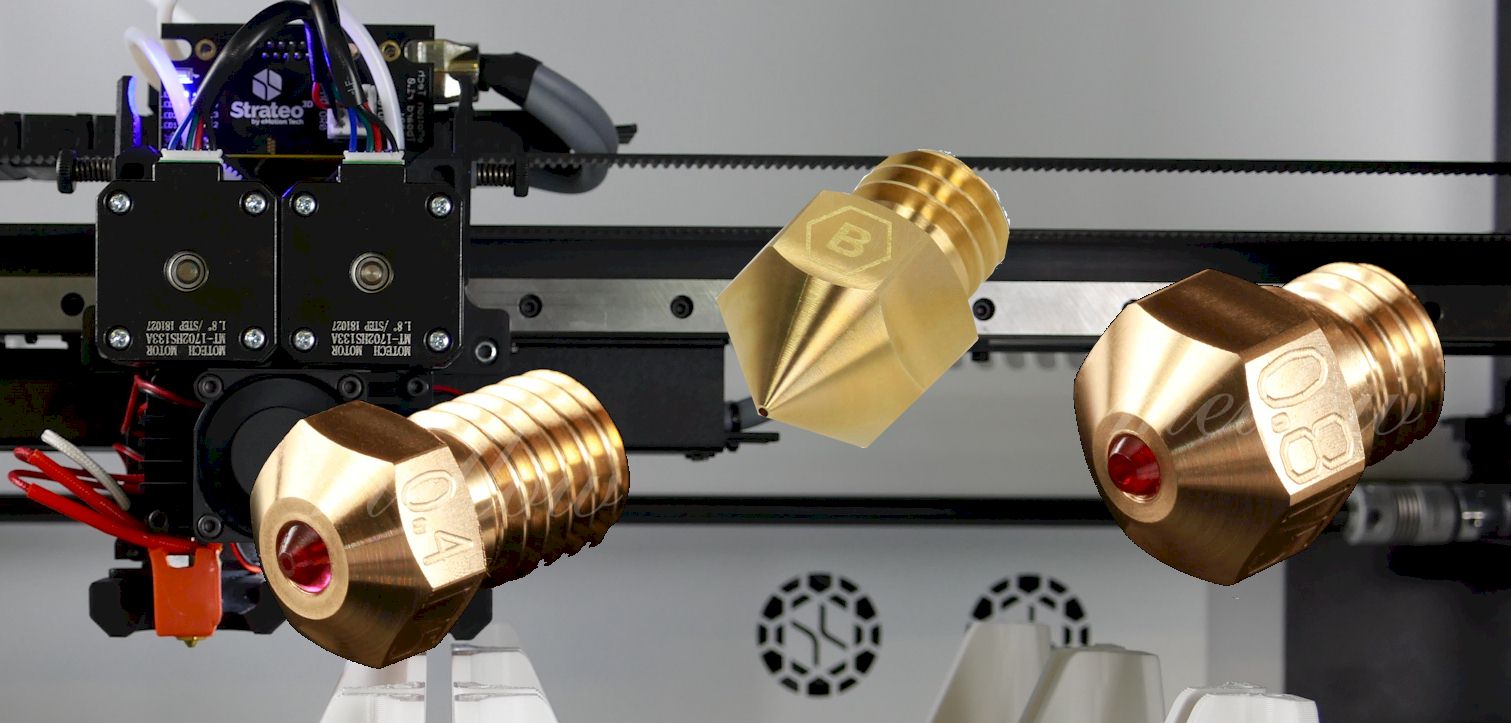

What are Mk8 and Mk10

Mk8 and mk10 are among the best and most common nozzles used on many 3D printers. Do you see how different phone brands produce various series of their phone? You can observe how phone manufacturers keep advancing the next series they release and have advanced features.

The same way the phones release phones is for the nozzle, extruder, and hot end of 3D printers. I gathered that the series started with mk1, and now they have released up mk11. However, the most common are mk6, mk10, and mk8.

The nozzle, extruder, and hot end combined make up a system where the filament passes through during printing. Each 3D printer has a series of nozzle systems compatible with and those they don’t. The reason why Mk8 and Mk10 are familiar is that they are consistent with several 3D printers.

Related: How to clean 3d printer nozzle

Mk8 vs. Mk10 Comparison

As mentioned before, mk8 and mk10 are just a series of 3D printer extruders. So what similarities and difference do they have that makes them comparable.

Below is a table showing a side-by-side comparison of the two extruders.

Properties of Mk8

- Nozzle shape: sharp and angled

- Compatibility: compatible with many printers

- Range of material used: Fewer materials

- Thread used: Mk6

- Thread diameter: 6.0 mm

- Reliability: more reliable

- Durability: durable

- Speed: slower

- Ease of use: easy

Properties of Mk10

- Nozzle shape: flat

- compatibility: less compatible

- Range of material used: more materials

- Thread used: Mk7

- Thread diameter: 7.7 mm

- Reliability: quite reliable

- Durability: durable

- Speed: faster

- Ease of use: easy

We will discuss each differently, giving you pros and cons so that you have an easy time choosing your nozzle.

About Mk8

Mk8 stands for a Makerbot Replicator. When this nozzle system was released, it came with a cooling bar thicker than the predecessor Mk7. The upgrade from the mk7 had some evolution on the design of the nozzle.

Mk8 nozzle is a bit sharper, and there are some angles on the tip of the nozzle, which was vastly different from the previous flat nozzles. In addition, the tapered nozzle regulates the amount of filament disposed of during printing.

Most 3D printers compatible with Mk8 are compatible with Mk6. This is because Mk8 and Mk6 use the same size of threading.

Another cool thing to expect on An Mk8 is a dual extruder, which allows the use of different colors and materials when printing. You can therefore customize the shape of the print you want.

Pros

- Mk8 is more precise than mk10.

- This extrusion system is ideal for detailed printing like jewelry.

- You can customize your print with different colors due to the dual extrusion feature.

- You can clean mk8 easily.

- Mk8 nozzle systems are pretty high quality.

- These extruders are compatible with many printers. For example, you can use an Mk6 in place of mk8.

Cons

- Height limit

- You cannot use a lot of materials when printing using an Mk8.

- You may frequently replace the nozzle depending on which material you are using.

- Mk8 HotEnd system is relatively slower than the likes of Mk10.

About Mk10

Mk10 is a Makerbot Replicator with more advanced features than mk9 and the rest of the Mk-series. This HotEnd system uses mk9 as a base model and uses Mk7 threads.

Mk10 extruder system has a large PTFE tube. Therefore the threads of the previous series Mk6, Mk8, Mk9 cannot fully cover the PTFE tube.

Pros

- Mk10 extruder is faster than mk8

- You can print huge items when using an Mk10

- You can use heavy materials to publish.

- The large thread of Mk10 ensures that the filament does not stick inside the PTFE tube.

- You can use various materials that other printers use and those they can’t.

Cons

- Not compatible with many printers.

- You cannot customize your prints. The large nozzle can’t produce high-quality prints.

Comparison between Mk8 and Mk10

Know that you have some information about the different features of the two extruders. We will use the table above to explain the other components.

- Nozzle shape:

The shape of the nozzle determines how easy it will be to control the filament coming out through extrusion. For example, when a nozzle is flat, the amount of filament passing is more. Whereas when the nozzle is angles and sharp, you can regulate the amount of material passing.

Mk8 has a sharp and angled nozzle. This is the reason it produces high-quality 3D prints. On the other hand, the nozzle on the Mk10 is flat.

- Compatibility and range of materials.

Since Mk8 uses the same thread size as mk6, it is compatible with printers that use Mk6 extruders. Before M8, there was a slight difference in the previous series of Mk. That is the reason all the others looked the same.

Mk10 uses mk9 as the base and mk7s thread. It is therefore compatible with fewer 3D printers.

When it comes to the range of materials, mk10 accommodates more materials than Mk8. For example, you can use heavy, thicker, and rigid materials with Mk10 extruder, while only a few flexible materials can be used with Mk8.

- Thread used

The size of the thread used determines the range of materials that can be used on the printer.

Mk8 uses an Mk6 thread, while Mk10 uses an Mk7 thread size. This means that 3D printers that use Mk7 extruder can use Mk10 and those compatible with Mk6 are also compatible with mk8.

The thread for Mk10 is quite large, with diameters of about 7.7mm. This is the reason you can use heavy materials when using Mk10.

Mk8 thread is about 6mm. It is also has a narrow nozzle hole. Therefore, it is ideal for jewelry making and other sophisticated, high-quality prints. However, the narrow nozzle does not accommodate several materials.

- Reliability and Durability

How long a component will serve you determines if it is worthy.

Mk8 is quite reliable for customizable smaller 3D prints, while Mk10 is reliable for large images.

You will need to change the filament often when using the Mk8 extruder. On the other hand, you can use heavy materials on the Mk10. The nozzle will not allow the material to be stuck on the inside of the PTFE tube.

Therefore both extruders are reliable when it comes to different functions. Mk10 is quite durable and does not need regular change and maintenance.

It is easy to clean mk8 when it is offline.

Related: How to replace nozzle on ender 3 pro

So what extruder do I choose?

Since now you know what to expect with each extruder, you may be asking yourself how you know the right extruder you will use with your 3D printer. There are several factors that you should consider when choosing an extruder.

Compatibility

Mk8 and Mk10 use different sizes of thread. Therefore not all printers can use the two types. However, I have seen instances where people buy an mk10 for their printer, Mk8.

Before buying a nozzle, check the type of extruder your 3D printer came with and its name. Check the user manual. There must be somewhere recorded the type of extruder used.

Consult the internet if you are not sure how an Mk8 or Mk10 looks. Many informative videos tell the difference and show how each extruder looks.

The type of material you are using.

If you plan to use heavy materials, then Mk10 should be your choice. This extruder has a comprehensive nozzle whole and a long PTFE tube. So no material will get stuck inside the tube.

On the other hand, Mk8 is narrow and short. Therefore, it only accommodates flexible materials. If you use thicker and rigid materials with Mk8, it will jam.

The type of project you are doing.

The type of extruder you use in one project is not used in others.

If you want to print colorful jewelry, you should use Mk8, a dual extruder feature. However, if you’re going to a large printing without too many details, use Mk10 in your printer.

Remember that you should check the type of extruder your printer uses.

The last thing you should consider is the amount of heat generated by your hot end. If your printer produces a lot of heat, it would be best to use an Mk10 extruder. Mk10 is fast and more extended; therefore, the filament deposits consistently.

Main tip

Make sure the nozzle you are considering buying is compatible with your printer.

For example, an Mk8 has a sharper nozzle tip, while Mk10 is almost flat.

How do You Change the Nozzle System?

So you wonder if the nozzle is just a simple component that has significance on the 3D printer. The answer is yes. When the HotEnd melts the filament and travels through the PTFE tube, the nozzle is the last place that shapes your print.

Due to tear and wear and different materials passed through the nozzle.

Hobbyists change the nozzle after three months. However, if you don’t use your printer frequently, you can change the nozzle twice a year.

If you want to change the nozzle, it is not a tedious process. So long as you know the type of extruder your printer uses, you can buy new nozzles.

Follow the following tips when changing the nozzle.

- To make the nozzle loose, heat. Sometimes the nozzle is too tight due to expansion after too much printing.

- Avoid touching the nozzle after heating. Several maintenance tools come with 3D printers. Use tools rather than your hands when removing nozzles.

- Add the new nozzle with the tools. This is to make sure the nozzle is tight enough to avoid leaking.

- Test if the nozzle is working. The last step is to print to test if the nozzle is working. If it is still not working after replacement, you can check other components.

Frequently Asked Questions

- Are Mk8 and Mk10 the only best nozzles?

There are quite a variety of nozzles in the market.

The two are common because they are compatible with most printers.

However, they also have several unique features like a dual extrude. - How different is Mk8 from Mk7?

Mk7 is 7th in the Makerbot Replicator series of nozzles, while Mk8 is the 8th.

Mk8 has a sharper, narrower, and angled tip, while mk7 is flat.

Mk8 also has the same thread size as M6. But Mk7 has a thread size the same as Mk10. - I unknowingly bought an Mk8 instead of Mk10. Can I use Mk8 in my 3D printer if the original nozzle was an Mk10?

Mk10 and Mk8 have different sizes of threading. Therefore, printers that are compatible with Mk10 cannot use Mk8.

Unfortunately, you will have to buy Mk10. Furthermore, Mk8 has a height limitation. - Are all nozzle systems made of metal?

The most common printers have metallic nozzles. However, there are several excellent plastic, brass, and copper nozzles.

The only problem is that the brass nozzles might react to some materials.

Plastic nozzles get damaged easily.

Conclusion

There is no good or lousy nozzle. It all depends on the type of printer you are using and the type of work you are doing.

Mk8 has a dual excluder feature. So you can use different colors at the same time for beautiful projects. The most significant limitation of using an Mk8 is that you have a limit on the materials you can use.

Mk10 is broad in that it allows all the material to be deposited without getting stuck. Moreover, the nozzle of Mk10 accommodates high speed. There you will finish a project faster.

So each of the nozzles has its downside and advantage. First, make sure you have read the user manual of your printer. There is where all the information about your computer is stored. This includes the type of nozzle used in your printer.

Contents